Product introduction

The mine agitation tank is an indispensable equipment in the flotation process. It is mainly used for the agitation of the pulp before flotation, so that the ore particles are suspended and fully contacted and mixed with the chemicals to create conditions for the sorting operation. The machine is widely used in black and non-ferrous metal concentrators, chemical, slurry mixing, cyanide plants and sewage treatment plants.

Mining tank equipment is used for slurry mixing and storage, not only for concentrators, but also for other industrial production sectors. When the black, non-ferrous metal concentrate slurry and coal slurry are piped, a large agitated storage tank is also required.

Product Advantages

1. Compact structure, good sealing performance, and set gray ash plate at the feeding port to prevent water mist from collapsing;

2. Stirring evenly, the stirring blade is fan-shaped, and the contact area with the medium is large when stirring;

3. The nozzles are arranged in multiple rows, the water volume is uniform and adjustable;

4. The residual ash rate is low, and the watershed setting at the bottom of the box ensures that there is no dead space in the equipment.

5. Mine mixing drum equipment has advanced performance, stable finished product quality, uniform mixing and rapid discharge.

operating principle

The slurry is discharged from the lower end of the impeller in the axial direction under the rotation of the impeller of the axial flow propeller blade, and a negative pressure is formed in the impeller chamber, so that the slurry flows into the impeller chamber from the impeller to be replenished. At the same time, under the diversion of the steady flow plate, the slurry forms a vertical circulating flow in the groove downward and upward in the center. When the upflow velocity of the slurry is greater than the sedimentation velocity of the ore pellet, the ore particles in the slurry are in suspension and maintain a uniform concentration.

Technical parameters

model | Diameter(mm) | Height(mm) | volume(mm) | Impeller dia(mm) | speed(r/min) | motor | weight(kg) | |

model | power(kw) | |||||||

(mm) | ||||||||

XB-750 | 750 | 750 | 0.26 | 240 | 530 | Y90S-4 | 1.1 | 228 |

XB-1000 | 1000 | 1000 | 0.58 | 240 | 530 | Y90L-4 | 1.5 | 436 |

XB-1200 | 1200 | 1200 | 1.14 | 400 | 320 | Y100L2-4 | 3 | 765 |

XB-1500 | 1500 | 1500 | 2.2 | 400 | 320 | Y100L2-4 | 3 | 1083 |

XB-2000 | 2000 | 2000 | 5.46 | 550 | 230 | Y132M2-6 | 5.5 | 1671 |

XB-2500 | 2500 | 2500 | 11.2 | 650 | 200 | Y160L-6 | 11 | 3438 |

XB-3000 | 3000 | 3000 | 19.1 | 700 | 210 | Y225S-8 | 18.5 | 4613 |

XB-3500 | 3500 | 3500 | 30 | 850 | 230 | Y225M-8 | 22 | 7110 |

PRODUCTS PRODUCTS

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

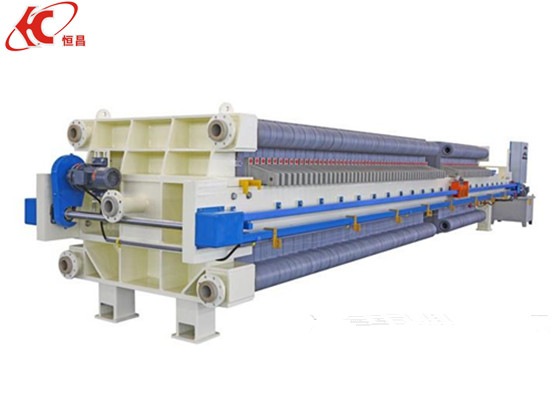

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website