Product introduction

Hammer crusher is suitable for crushing medium and fine crushing of materials with medium hardness, such as limestone, slag, coke, coal, etc.

Hammer crusher mainly depends on impact energy to complete the crushing material operations. Hammer crusher is working, the motor drives the rotor high-speed rotation, the material into the crusher chamber evenly and high-speed rotary hammer impact, cut apart the material to the material being broken, at the same time, the material's own gravity makes material from the high-speed rotating hammer head to the body panel, sieve, resistance is greater than the screen hole size of materials on the sieve plate continues to hit by the hammer and the grinding, crushing to the discharging granularity until the final through the sieve plate outside.

Product Advantages

operating principle

When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them, the crushed products meeting the required size can be discharged by the outlet and become the final products, the large size products are brought back to the crushing area by the hammers for being re-crushed until they reached the required size. When the bulk material into the machine, hit by the hammerhead and stopped by material bracket. That's not only increase the contact area between material and hammerhead but also avoid sudden infarction of the rotor. After the impact, bulk materials hit themselves on the crushing cavity. Then the stones overflow from the straight screen or falling and been hammered again forming the stones. At last discharged from outlet of the hammer crusher.

Technical parameters

Model | Rotor Size | Rotor Speed | Feeding Size | Output Size(mm) | Motor power | Capacity(t/h) | Weight |

PC400×300 | Φ400×300 | 1440 | ≤100 | ≤10 | 7.5 | 5-10 | 900 |

PC600×400 | Φ600×400 | 960 | ≤100 | ≤15 | 18.5 | 10-20 | 1500 |

PC800×600 | Φ800×600 | 970 | ≤120 | ≤15 | 45 | 18-24 | 2680 |

PC1000×800 | Φ1000×800 | 990 | ≤200 | ≤15 | 110 | 30-50 | 5600 |

PC1000×1000 | Φ1000×1000 | 990 | ≤200 | ≤15 | 132 | 30-60 | 8000 |

PC1200×1200 | Φ1200×1200 | 750 | ≤250 | ≤20 | 180 | 90-110 | 19000 |

PRODUCTS PRODUCTS

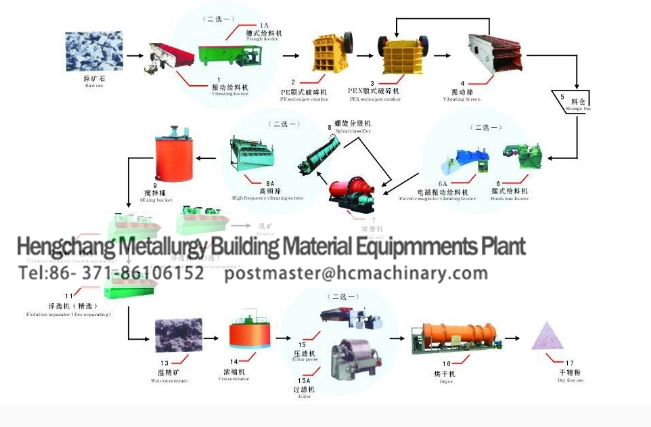

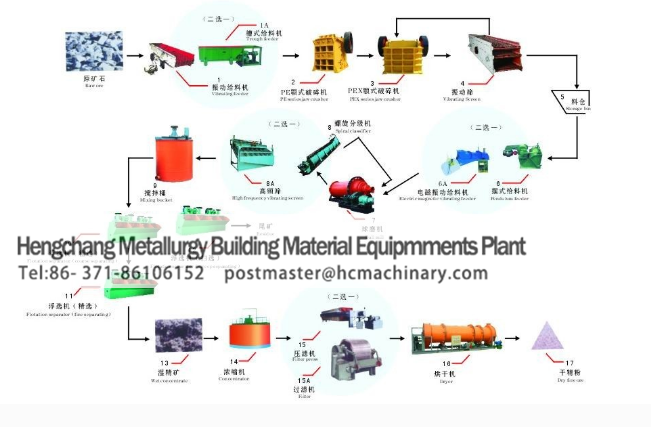

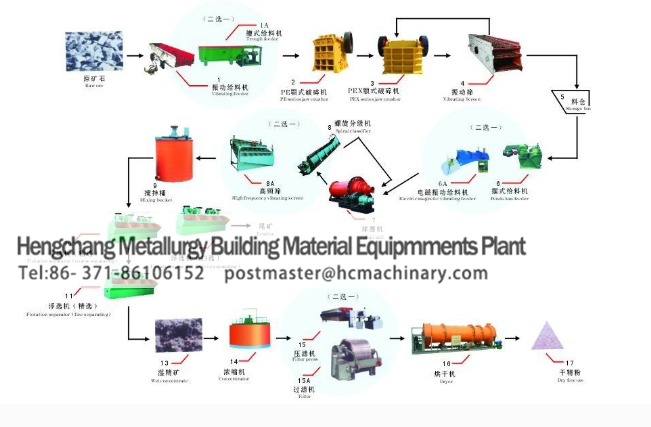

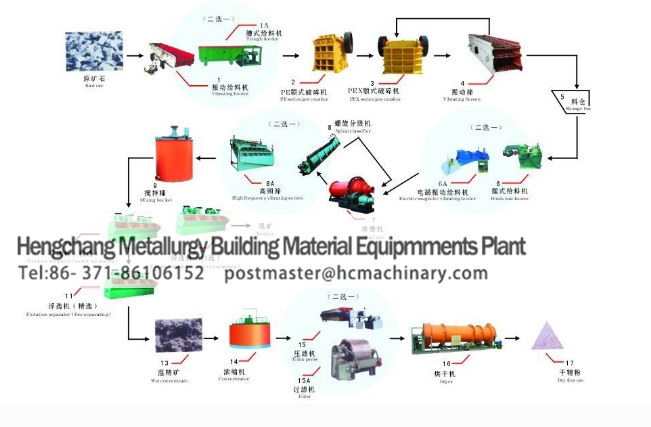

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

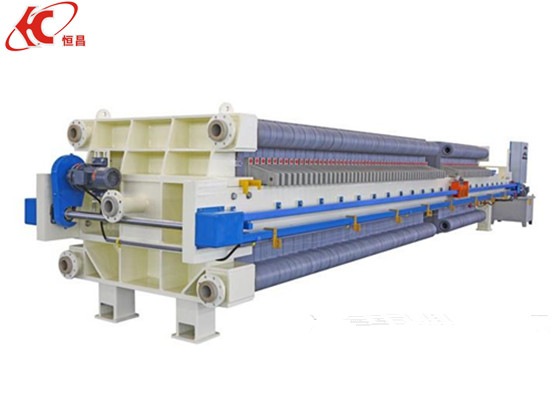

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website