Product introduction

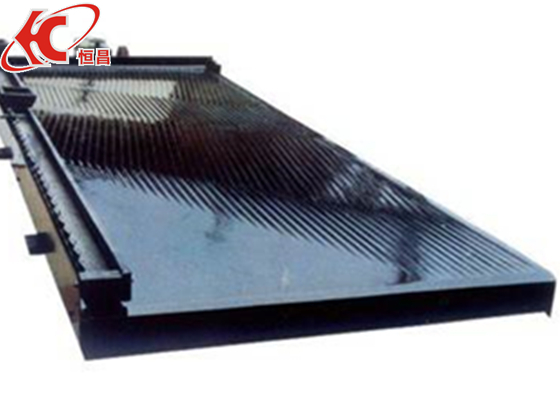

Shaking Table Separation is one of the important dressing equipment depending on the gravity. It is widely used in to classify the granularity 2-0.02 millimeters ore and ore slime of tungsen, tin, niobium, manganese, chromium, titanium, lead , zinc, gold, iron(rediron, brown iron) and so on metallic minerals.

It is easy to be operated and can prduce high grade concentrated ore, secondary concentrated ore, middlings and gangue, etc at the same time, it is widely used to separate tungsten, stanum, niobium,gold, other rare metal and nobel metal ores, it can also be used to separate iron, manganese minerals, coal and so on.

Product Advantages

1. Get concentrate and gangue at one time

2. Fine water-resistance, chemical resistance, corrosion resistance, abrasion resistance, etc;

3. We can simplify the repair and painting process, which directly reduces the maintenance cost, greatly increases recovery

rate, and prolongs the life of ore concentration tables.

4. High enrichment ratio, good selection effect, easy operation

5. Low energy consumption, competitive price

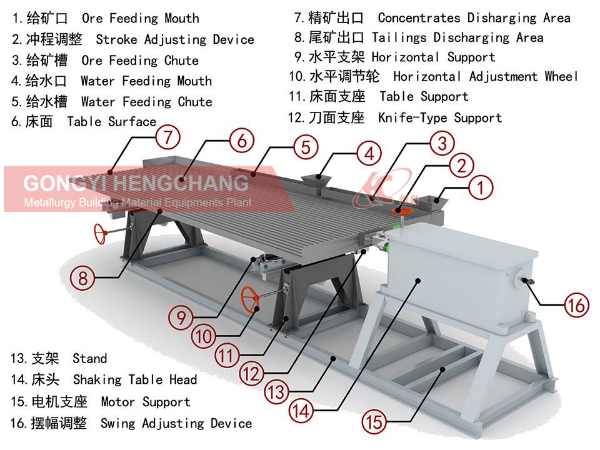

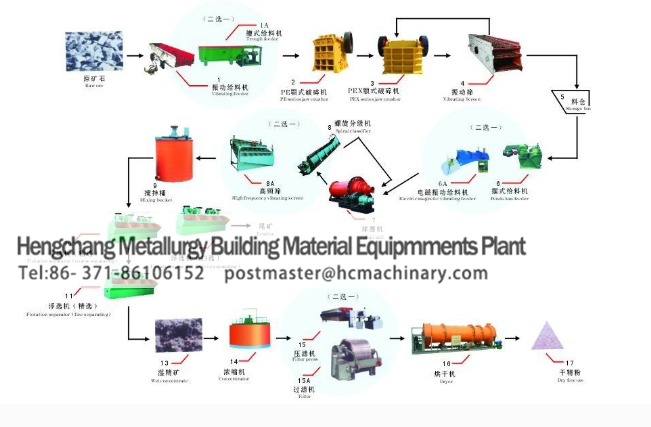

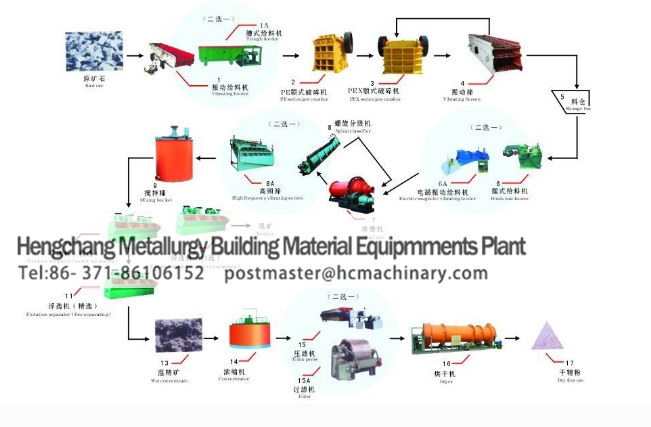

operating principle

Shake table is on the lean table board with raffles. The ore material is fed in by the feeding chute upper table board; meanwhile,the water

is fed by water feeder transversely. Under the impact of vibrating wave, the materials go on vertical and horizontal movement as per the

different proportion and granularity. The ore material with different proportion and granularity move down in laddershipped state along with

their own movement, then discharge from the fine concentrate end and tailings end, finally they are separated out to fine concentrate, middle

concentrate and tailings.

Technical parameters

Model | Bed Size | Max. Input Size | Stroke (mm) | Water | Area | Bed | Power | Weight |

Coarse Sand | 4450*1855*1546 | 2 | 16-22 | 80-150 | 7.6 | Rectangle | 1.1 | 780 |

Fine | 4450*1855*1546 | 0.5 | 11-16 | 30-60 | 7.6 | Sawtooth | 1.1 | 780 |

Sand | 4450*1855*1546 | 0.15 | 8-16 | 10-17 | 7.6 | Triangular | 1.1 | 780 |

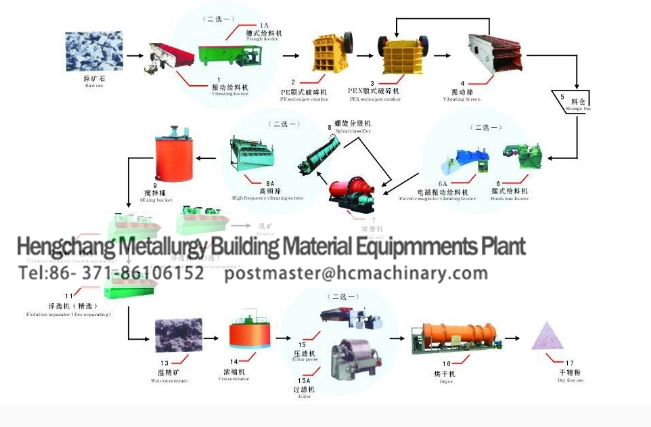

PRODUCTS PRODUCTS

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

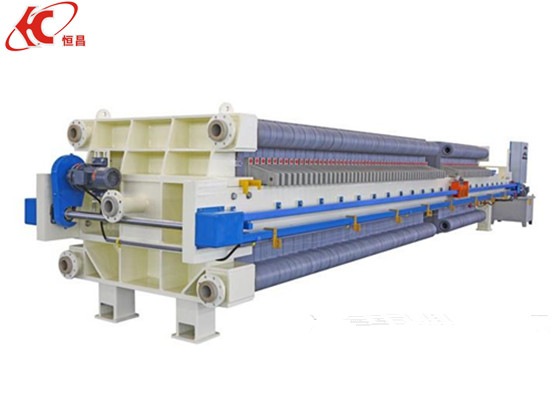

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website