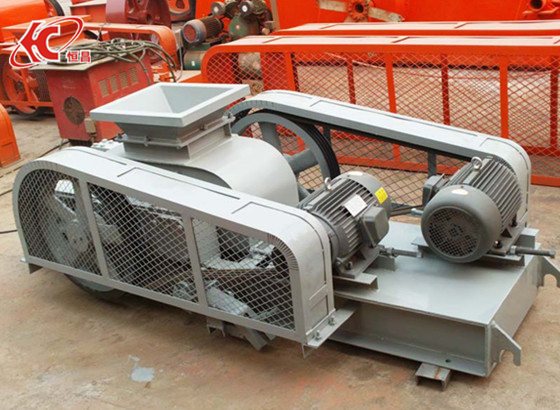

Product introduction

Double Roller Crusher is a mining machinery, also called double roll crusher. Mainly used for crushing ore. This machine has a small size, large crushing ratio (5-8), low noise, simple structure, easy maintenance advantages of the material to be broken,, uniform particle size, over crushed low, easy maintenance, overload protection is sensitive, safe and reliable. For coal, metallurgy, mining, chemicals, building materials and other industries more suitable for large-scale coal or coal preparation plant (including gangue) broken. Roll crusher capacity, coupled with the limited pitch type fluid coupling between the motor and reducer to prevent power overload, overload sensors, safe and reliable. Roll spacing hydraulic adjustment, toothed roller bearing concentrated lubrication. Tooth design optimization, select the shear pull crushing, high efficiency and low consumption, the grain evenly.

Product Advantages

1. Compact structure, light weight, small size, for grinding system required the same production capacity, equipment PDG-II roll crusher can significantly save investment.

2. Simple structure, small footprint, operation and maintenance more convenient.

3. The interior is equipped with dust-proof plate, good sealing performance, avoiding splashing Young crushed fine material, dust, low noise operation, the working environment has greatly improved.

operating principle

It`s working mechanism is two cylindrical rollers. The roller is supported by a fixed bearing and a movable bearing. The two rollers are relatively rotated by the motor. The material crushes the material by the friction of the two rotating rollers, and the broken material is discharged from the two rollers by gravity. The spring is sufficient to balance the pressure generated between the two rolls. If there is a non-crushed material falling between the two rolls, the bearing compression spring can be pushed open to cause a large gap to pass the non-crushed material. After the non-crushed material passes, the spring can keep the gap between the two rolls to the original size and continue to work.

Technical parameters

Model | Rotor size (mm) | Feeding size(mm) | Output size(mm) | Capacity (t/h) | Motor power(kw) | Weight (kg) |

2PG400*250 | 400*250 | <=25 | 2-5 | 5-10 | 5.5*2 | 1500 |

2PG600*400 | 600*400 | <=40 | 2-10 | 10-20 | 15*2 | 4500 |

2PG750*500 | 750*500 | <=40 | 2-20 | 15-40 | 18.5*2 | 8900 |

2PG900*500 | 900*500 | <=40 | 3-40 | 20-50 | 22*2 | 14000 |

PRODUCTS PRODUCTS

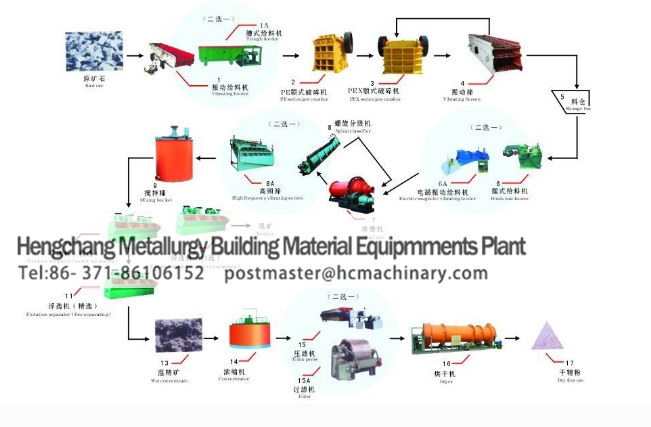

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

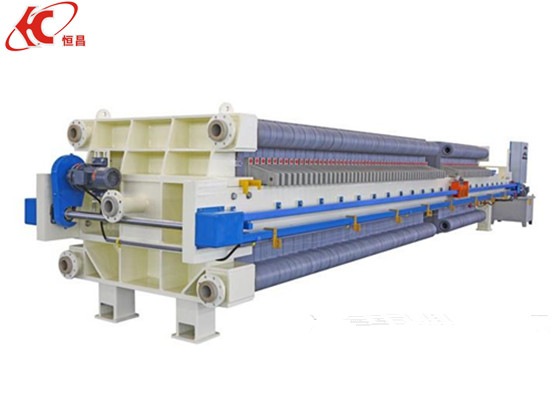

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website