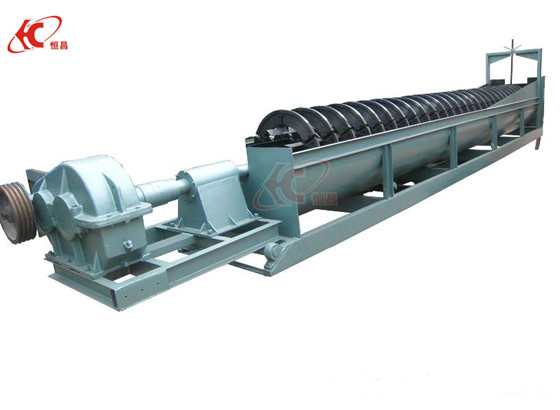

Product introduction

The spiral sand washing machine is a kind of sand washing machine. The sand material is mainly stirred by the screw device in the equipment, so that the soil in the sand stone material is mixed with water, and is discharged from the flow port on the equipment, and the sand stone material is in the Under the action of the screw device, it is gradually screened and discharged from the discharge port at the top, thereby achieving the cleaning and screening effect of the sand and gravel material.

Spiral sand washing machine is especially suitable for making abrasive, refractory materials, cement, quartz sand, steel sand, slag powder, copper ore, iron ore, gold ore, concrete aggregate, asphalt aggregate and other hard and brittle materials. Fine and medium crushed, it is an efficient and energy-saving gravel sand making equipment, which is 50% more energy efficient than traditional sand making machines.

Product Advantages

1. Simple structure and stable operation.

2. The bearings are separated from the water and materials to avoid premature damage caused by pollution and rust.

3, suitable for a variety of work environments.

4. The material to be washed has less loss and the cleaning efficiency is high, which can fully meet the requirements of high-grade materials.

5, the service life is relatively long, almost no wearing parts.

6, in rare cases need to be repaired, so it can greatly reduce costs.

operating principle

When the spiral sand washing machine works, the motor rotates slowly through the V-belt, reducer and gear, and the impeller rotates slowly. The gravel has a feed trough into the washing tank, which is tumbling under the impeller and rubbed against each other to remove the surface of the gravel. Impurities, at the same time destroying the water vapor layer of the coated sand to facilitate dehydration; at the same time, adding water in the opposite direction of the sand, forming a strong water flow, taking away foreign matter with small impurities and small specific gravity in time, and discharging it from the overflow port to complete the cleaning. effect. The clean sand is taken away by the blades, and finally the sand is poured from the rotating impeller into the discharge chute to complete the cleaning of the sand.

Technical parameters

Model | Spiral Dia.(mm) |

Rotate Speed (r/min) |

input Size (mm) | Water Consumption (T/h) | Capacity (T/h) | Power (Kw) | Weight (Kg) |

LXS -508 | Φ508 | 38 | ≤10 | 6-40 | 20-30 | 5.5 | 2670 |

LXS -610 | Φ610 | 32 | ≤10 | 6-50 | 30-40 | 7.5 | 3800 |

LXS -762 | Φ762 | 26 | ≤10 | 9-63 | 75 | 11 | 4020 |

LXS -914 | Φ914 | 20 | ≤10 | 10-80 | 100 | 11 | 6500 |

LXS-1118 | Φ1118 | 18 | ≤10 | 27-168 | 175 | 15 | 8690 |

LXS -1500 | Φ1500 | 13 | ≤10 | 27-180 | 220 | 18.5 | 16580 |

2LXS -762 | Φ762 | 26 | ≤10 | 136-182 | 145 | 11×2 | 8140 |

2LXS -914 | Φ914 | 21 | ≤10 | 120-150 | 200 | 11×2 | 13500 |

2LXS-1118 | Φ1118 | 17 | ≤10 | 200-250 | 300 | 15×2 | 19800 |

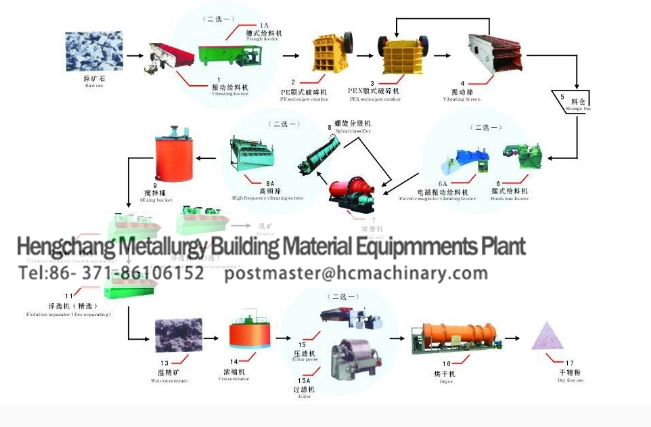

PRODUCTS PRODUCTS

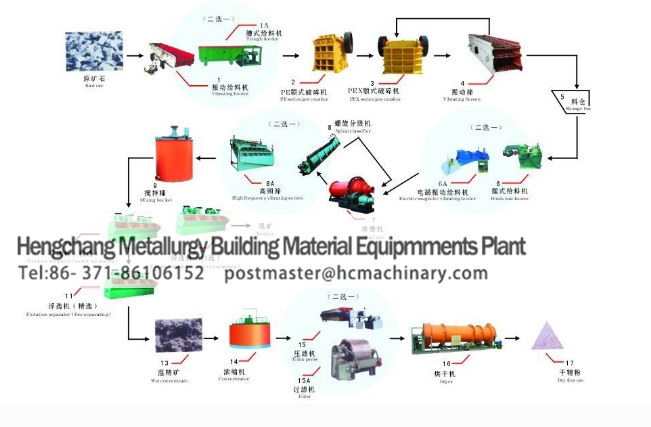

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

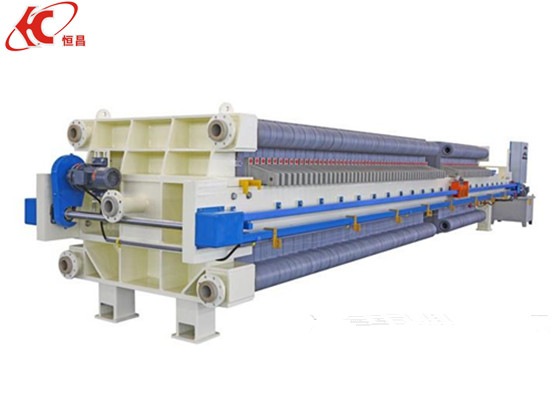

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website