Product introduction

The multi-cylinder hydraulic cone crusher is a typical crushing device for medium and fine crushed hard materials. It is developed on the basis of the spring cone crusher, and its basic structure is similar to that of the spring cone crusher. Used in mining, metallurgy, construction, chemical, electric power, transportation and other industries.

Structure and composition

The multi-cylinder hydraulic cone crusher mainly consists of a fixed cone part, a moving cone part, an eccentric sleeve part, a transmission part, a frame part, an adjustment ring part, a feed bin part, a discharge port adjustment part, a lock protection cylinder part, and a fan part. , motor department, hydraulic station, lubrication station and special tool parts.

Product Advantages

(1) Increase the eccentric moment and improve the processing capacity;

(2), speed up, increase power, increase the fineness of crushing;

(3), raise the moving cone selection center, optimize the cavity design;

(4) Thickening of the lining plate to extend the life;

(5), the hydraulic motor replaces the hydraulic push rod device, and the fixed cone assembly is removed in 10 minutes;

(6) High production and mineral content;

(7), the key components are made of high-strength materials, and the weight is increased appropriately, and the reliability is higher.

operating principle

The multi-cylinder cone crusher is a typical crushing device for medium and fine crushed hard materials. When working, the moving cone makes a swinging motion along the inner surface. Near the fixed cone, the material is crushed by the extrusion and bending of the moving cone. When the moving cone is offset, the broken material falls from the bottom of the cone due to gravity. The crushing and discharging processes are successively performed sequentially along the inner surface. The lock protection cylinder is composed of a plurality of lock protection cylinders, an over-iron protection accumulator, a buffer accumulator group and a pipeline. The locking protection cylinder mainly functions as iron protection and cleaning the crushing chamber. Each two hydraulic cylinders are equipped with a buffer accumulator. When the normal crushing is used, the adjusting ring jumps due to a few hard materials during the buffering.

Technical parameters

Model | Cavity (coarse/fine) | Close Side feed opening(mm) | Min CSS (mm) | Capacity (t/h) | Power KW(HP) |

HCHP300 | C1 Extra Coarse | 230 | 25 | 220-440 | 250(350) |

C2 Coarse | 210 | 20 | 190-380 | ||

M Medium | 150 | 16 | 175-320 | ||

F1 Fine | 105 | 13 | 110-260 | ||

F2 Extra Fine | 80 | 10 | 100-240 | ||

HCHP500 | C1 Extra Coarse | 330 | 38 | 425-790 | 400(500) |

C2 Coarse | 290 | 30 | 380-700 | ||

M Medium | 210 | 22 | 330-605 | ||

F1 Fine | 130 | 16 | 270-535 | ||

F2 Extra Fine | 95 | 13 | 200-430 | ||

HCHP800 | C1 Extra Coarse | 350 | 38 | 545-1200 | 630(850) |

C2 Coarse | 300 | 32 | 495-1050 | ||

M Medium | 265 | 25 | 470-950 | ||

F1 Fine | 220 | 17 | 385-730 | ||

F2 Extra Fine | 150 | 14 | 310-600 | ||

F3 Extra Fine | 90 | 10 | 260-550 |

PRODUCTS PRODUCTS

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

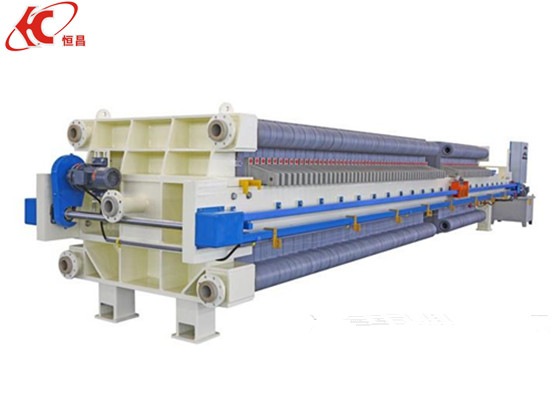

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website