Product introduction

Mobile Jaw crusher station is a kind of new rock crushing equipment, mainly used in metallurgy, chemical industry, building materials, water and electricity and other materials processing, often need to move operations especially for highway, railway, water and electricity engineering, such as liquidity stone operation, the user can according to the types of processing raw material, the requirements of different size and finished product material using a variety of configuration forms.It is widely used in the recycling and reuse of mine, coal mine waste and construction waste, soil and stone works, urban infrastructure works, roads or construction sites and other site operations to deal with topsoil and other materials;Separation of viscous aggregate;Construction and blasting industries;Sieve after crushing;Artificial sand production of tailings from river, pebble and mountain stone (limestone, granite, basalt, diabase, andesite, etc.) in quarrying industry.

Product Advantages

1, The integration of the whole set of units the integration of the unit equipment installation form, eliminating the complex site infrastructure installation of separate components, reduce the consumption of materials and labor.The reasonable and compact space layout of the unit improves the flexibility of site stationing.

2, the mobile jaw crusher station with flexible mobility has a high vehicle-mounted site, the width of the vehicle body is smaller than that of the semi-trailer, and the turning radius is small, which is convenient for driving on ordinary roads and more convenient for driving in the rugged and harsh road environment in the crushing field.Save time for quick entry to site.It is more conducive to stationed in the reasonable construction area and provides more flexible space and reasonable layout for the overall crushing process.

3, the mobile jaw crusher plant can reduce the cost of material transportation. It can crush the materials on the spot at the first line, eliminating the intermediate link of material transportation from the site and crushing again, greatly reducing the cost of material transportation.In addition, the extended unit can directly transfer the broken materials into the bin bin, transfer from the site.

4, job role directly effective integration of jaw crusher mobile crushing station, can be used independently, can also according to customer the types of materials in the process, product requirements, providing a more flexible process configuration, meet user demands of mobile crushing, mobile screen classification, make production organization, logistics, transport more directly, to maximize the cost reduction.

5, strong adaptability and flexible jaw mobile crushing station, for coarse crushing, fine crushing screening system, can be single unit independent operation, also can be flexible system configuration unit joint operation.The side discharge of the discharging hopper provides the flexibility of various configurations for the sieving material transportation mode. The diesel generator in the configuration of the integrated unit can not only supply power to the unit, but also provide joint power supply to the process system.

operating principle

Material by the feeder evenly to the crusher, after crusher preliminary broken, closed-circuit system constructed by circular vibrating screen, realize the material cycle of broken, finished product material from the conveyor output, continuous broken jaw crusher mobile crusher can according to the actual production operation need to remove the circular vibrating screen, realize the material directly in preliminary broken, and other crushing equipment supporting the use convenient and flexible operation.

Technical parameters

Technical Parameter: | ||||||

HC Mobile Jaw crusher station | HC600 | HC750 | HC900 | HC1060 | HC1200 | HC1300PEX |

Transport Dimensions | ||||||

Length (mm) | 8600 | 9600 | 11097 | 13300 | 15800 | 9460 |

Width (mm) | 2520 | 2520 | 3759 | 2900 | 2900 | 2743 |

Height (mm) | 3770 | 3500 | 3500 | 4440 | 4500 | 3988 |

Weight (kg) | 15240 | 22000 | 32270 | 57880 | 98000 | 25220 |

Axle weight (kg) | 10121 | 14500 | 21380 | 38430 | 64000 | 14730 |

King pin weight (kg) | 5118 | 7500 | 10890 | 19450 | 34000 | 10490 |

Jaw Crusher | ||||||

Model | PE400×600 | PE500×750 | PE600×900 | PE750×1060 | PE900×1200 | PEX300×1300 |

Feed opening (mm) | 400×600 | 500×750 | 600×900 | 750×1060 | 900×1200 | 300×1300 |

Discharging hole setting renage (mm) | 40-100 | 50-100 | 65-180 | 80-180 | 95-225 | 20-90 |

Capacity (m3/h) | 10-35 | 25-60 | 30-85 | 70-150 | 100-240 | 10-65 |

Feeder | ||||||

Feed hopper volume (m3) | 3 | 4 | 7 | 10 | 10 | 3 |

Hopper width (mm) | 2200 | 2500 | 3000 | 3000 | 3000 | 2200 |

Model | GZT0724 | GZT0724 | GZT0932Y | ZSW490×110 | ZSW600×130 | GZT0724 |

Belt Conveyor | ||||||

Model | B650×6 | B800×7 | B1000×8 | B1000×11 | B1200×13 | B1000×7 |

PRODUCTS PRODUCTS

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

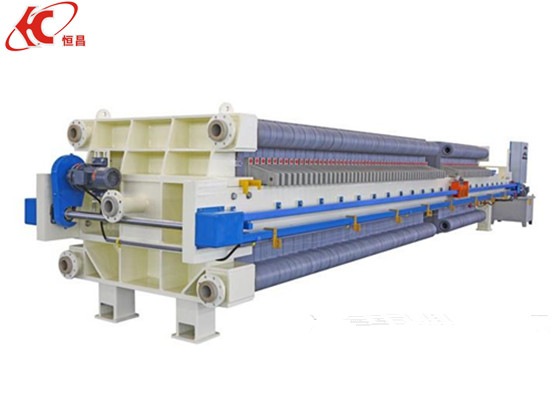

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website