Product introduction

YTS trommel screen is applied to materials classification and ore washing operation. The equipment has the advantages of simple installation and maintenance, easy operation, small installation slope, un-easy blocking, small space, low noise, low dust pollution, stable operation and high screening efficiency.

Product Advantages

1. The mesh hole is not easy to block.

2. The operation is stable and the noise is low.

3. Simple structure and convenient maintenance.

4, the screening cylinder can be closed, easy to close the dust collection.

5. The reliability of the whole machine is high, and the one-time investment is less.

6, the use of special mesh, high screening efficiency, long service life.

operating principle

The drum unit is mounted obliquely on the frame. The motor is coupled to the drum unit via a coupling through a reducer to drive the drum unit to rotate about its axis. After the material enters the roller device, due to the tilting and rotation of the roller device, the material on the sieve surface is turned over and rolled, so that the qualified material (the product under the sieve) is discharged through the discharge port at the bottom of the rear end of the drum, and the unqualified material (screen) The upper product is discharged through the discharge opening at the end of the drum. Due to the turning and rolling of the material in the drum, the material stuck in the screen hole can be ejected to prevent the screen hole from being clogged. The principle structure of the drum sander, the drum screener and the drum screen is almost the same, and there is a difference in people's understanding and calling.

Technical parameters

Model | Drum Size (mm)

|

Feed Size(mm | Screen Pore(mm) |

Capacity (t/h) | Rotary Speed(r/min) | Power (kw) |

Weight(t) |

YTS800×2000 | Φ800×2000 | ≤10 | 1-10 | 10-15 | 20 | 1.5 | 1.6 |

YTS 1000×2400 | Φ1000×2400 | ≤15 | 1-15 | 20-50 | 15-19 | 4 | 3.3 |

YTS 1200×3000 | Φ1200×3000 | ≤20 | 1-15 | 50-100 | 13-18 | 5.5 | 4.3 |

YTS 1500×3000 | Φ1500×3000 | ≤20 | 1-20 | 100-150 | 13-18 | 7.5 | 5.3 |

YTS 1500×4500 | Φ1500×4500 | ≤20 | 1-20 | 100-200 | 13-18 | 7.5 | 6 |

YTS 1800×4800 | Φ1800×4800 | ≤30 | 1-30 | 200-250 | 13-18 | 7.5 | 7.5 |

YTS 2000×4000 | Φ2000×4000 | ≤50 | 1-50 | 200-300 | 13-16 | 11 | 9 |

PRODUCTS PRODUCTS

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

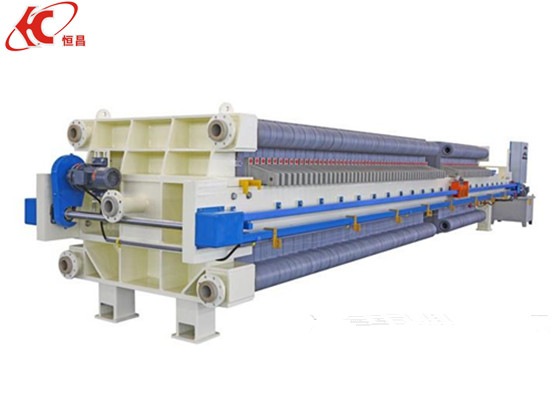

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website