Product introduction

The wet magnetic separator in our factory applies to the strong magnetic minerals with the particle size of less than 3mm, such as the magnetites , calcined ore, ilmenite ore, etc. In addition, it is also widely used for iron removal operation in coal, non-ferrous metal and building material industry. Our factory can supply different magnetic force grade seperator in the form of downstream, semi-counter current, counter current. It owns the features of simple structure, large capacity, easy operation and maintenance, etc.

Product Advantages

1. Reasonable structure, easy installation and operation,

2. Applicable to wet process

3. Permanent magnetic shell, the magnetic intensity on the shell surface can be designed according to actual application, with strong processing capacity and low maintenance cost.

operating principle

When the raw materials flow into the tank body of the magnetic separator firstly, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation. In the second step, the flushing water below flush the raw materials back is the second separation. This time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall in the ore concentrate box under the effect of gravity. the flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials can not be attracted and will flow to the discharge pipe as tailings.

Technical parameters

Model | Magnetic Strength (mT) | Input Size (mm) | Cylinder Speed (r/min) | Power (kw) | Capacity | Weight (kg) | |

Ore (t/h) | Slurry (m3/h) | ||||||

CTB600x900 | ≥120 | ≤1 | 40 | 1.1 | 8-15 | 24 | 850 |

CTB600×1200 | ≥120 | ≤1 | 40 | 1.5 | 10-20 | 32 | 1000 |

CTB600×1800 | ≥120 | ≤1 | 40 | 2.2 | 15-30 | 48 | 1300 |

CTB750×1200 | ≥120 | ≤1 | 35 | 2.2 | 15-30 | 48 | 1500 |

CTB750×1800 | ≥120 | ≤1 | 35 | 3.0 | 20-45 | 72 | 1800 |

CTB900×1800 | ≥135 | ≤1 | 28 | 4.0 | 25-55 | 90 | 2400 |

CTB900×2100 | ≥135 | ≤1 | 28 | 4.0 | 30-65 | 100 | 2650 |

CTB1050×1800 | ≥145 | ≤1 | 22 | 5.5 | 35-70 | 110 | 3800 |

CTB1050×2100 | ≥145 | ≤1 | 22 | 5.5 | 45-88 | 140 | 4150 |

CTB1050×2400 | ≥145 | ≤1 | 22 | 5.5 | 45-88 | 140 | 4500 |

CTB1200×2100 | ≥145 | ≤1 | 19 | 7.5 | 62-110 | 160 | 5800 |

CTB1200×2400 | ≥145 | ≤1 | 19 | 7.5 | 82-120 | 192 | 6200 |

CTB1200×3000 | ≥145 | ≤1 | 19 | 7.5 | 80-150 | 240 | 6800 |

CTB1500×3000 | ≥145 | ≤1 | 14 | 11 | 90-170 | 270 | 8200 |

CTB1500×4000 | ≥145 | ≤1 | 14 | 11 | 115-220 | 350 | 9000 |

PRODUCTS PRODUCTS

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

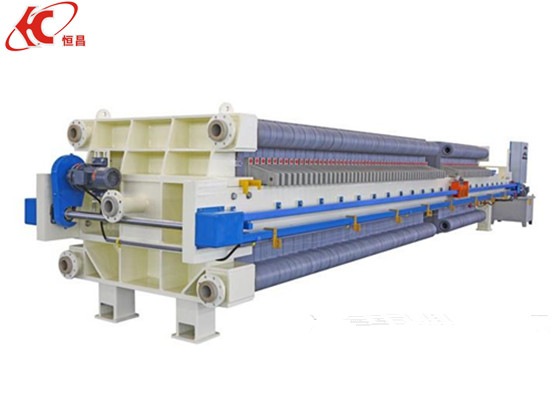

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website