Product introduction

The mobile cone crusher plant is mainly used in the field of fine crushing. In the sandstone production operation, according to different stone and finished products, the mobile cone crusher station replaces the impact crusher to produce sandstone products with higher hardness and finer grain size. Processing capacity, high efficiency, medium and fine strong crushing, strong adaptability, crushing and screening treatment, self-loading conveyor.

It is mainly composed of high-efficiency cone crusher, high-performance vibrating screen, belt conveyor, electric motor and control box. The cone crusher can be adjusted to different crushing chamber types according to actual needs, and the use field and scope of use of the medium crushing . The entire unit is installed and coordinated, which fully demonstrates the advantages of convenience and flexibility. The mobile crusher can be customized according to customer requirements, and the suitable cone crusher, vibrating screen, motor and other equipment can be customized according to the actual situation of the production site, greatly improving your production efficiency.

Product Advantages

1. Strong mobility: The length of the tire mobile crushing station is short. Different crushing equipments are installed on the independent movable chassis. The wheelbase is short and the turning radius is small. It can be flexibly driven on ordinary roads and working areas.

2. Integrated complete unit: The integrated unit equipment installation form eliminates the complicated site infrastructure installation work of the split components and reduces the material and working hours. The reasonable and compact space layout of the unit improves the flexibility of the station.

3. Reduce material transportation cost: The mobile crushing station can process materials on site without having to move the materials away from the site for further processing, which greatly reduces the transportation cost of materials.

4. The operation function is directly effective: the integrated series of mobile crushing stations can be used independently, or it can provide more flexible process configuration for the material type and product requirements of the customer, and meet the user's mobile crushing and moving screening. The requirements make the organization and logistics transfer more direct and effective, and the cost is maximized.

5. Flexible combination and adaptability: The tire mobile crushing station can be composed of “first crushing and then crushing” according to different crushing process requirements, or it can be composed of “first screening and crushing” process. The crushing station can be combined into coarse crushing according to actual needs. The fine crushing two-stage crushing and screening system can also be combined into a coarse crushing, medium crushing and fine crushing three-stage crushing screening system, and can also be operated independently without great flexibility.

operating principle

1. When cone crusher is working, motor drives the eccentric sleeve to rotate. The eccentric sleeve drives the transmission shaft and cone part to make swing movement. When they swing to the extent that the surface of the crushing wall is close to the roll mortar wall, the rocks and ores are pressed and crushed.

2. Joint between supporting sleeve and frame is compressed by spring. When metal block and other materials that can no be crushed fall into the crusher, spring will be out of sharp and discharge the objects.

3. When the materials that can not be crushed pass through the crushing chamber or the machine overloads, the spring safety system makes the cone discharging hole become larger. When objects are discharged from crushing chamber, discharging hole will automatically reset. Cone crusher resumes normal operations.

4. The surface of crushing chamber is covered with wear-resisting high manganese steel lining plate. Size of discharging hole can be adjusted hydraulically or manually.

Technical parameters

Technical Data//Model | Y3S1848CS75 | Y3S1860CS160 | Y3S1860HP220 | Y3S2160HP220 | |

Transportation size(mm) | 12000x2800x4300 | 13400x2820x4350 | 13400x2820x4350 | 13400x2820x4350 | |

Weight(t) | 28 | 46 | 42 | 43.5 | |

Tire Configuration | Dualaxial | Triaxial | Triaxial | Triaxial | |

Cone Crusher | CS75 | CS160 | HP220 | HP220 | |

Discharging Belt Conveyor | B800×6M | B800×8M | B800×8M | B1000×8M | |

Vibrating Screen | 3YZS1848 | 3YZS1860 | 3YZS1860 | 3YZS1860 | |

Electric control | standard | control box + control panel | control box + control panel | control box + control panel | control box + control panel |

Optional | Control box + LCD | Control box + LCD | Control box + LCD | Control box + LCD | |

Hydraulic leg | standard | 4 | 4 | 4 | 4 |

optional | 2 | 2 | 2 | 2 | |

Hydraulic cycliner | standard | 0 | 0 | 0 | 0 |

Optional | 2 | 2 | 2 | 2 | |

Genset(optional) (Kw) | 180 | 320 | 440 | 440 | |

PRODUCTS PRODUCTS

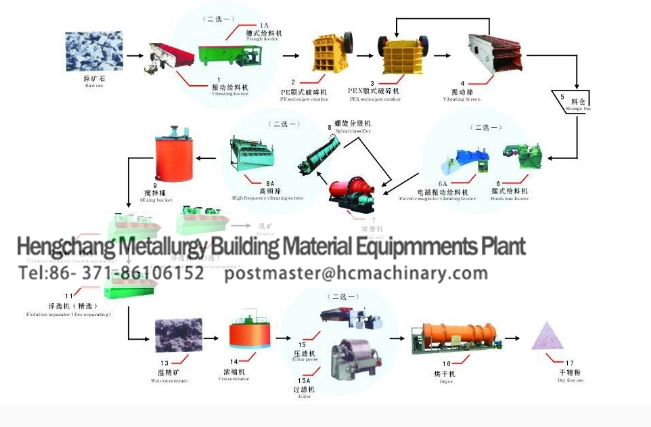

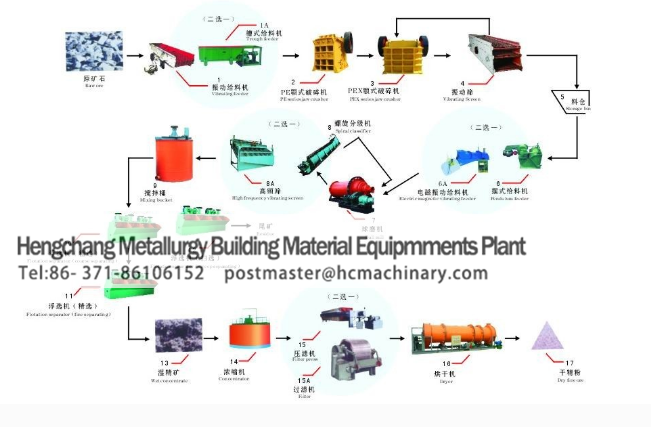

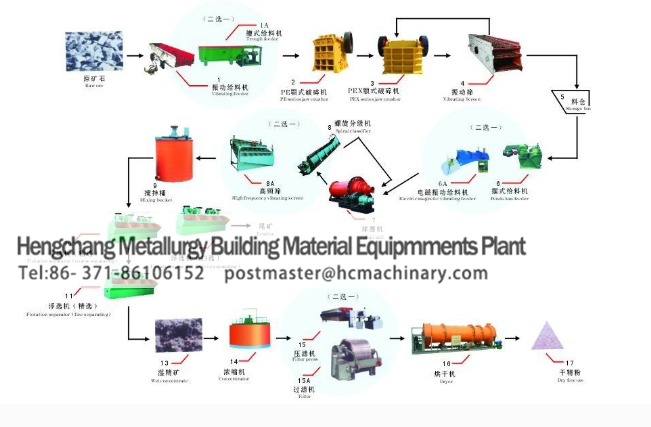

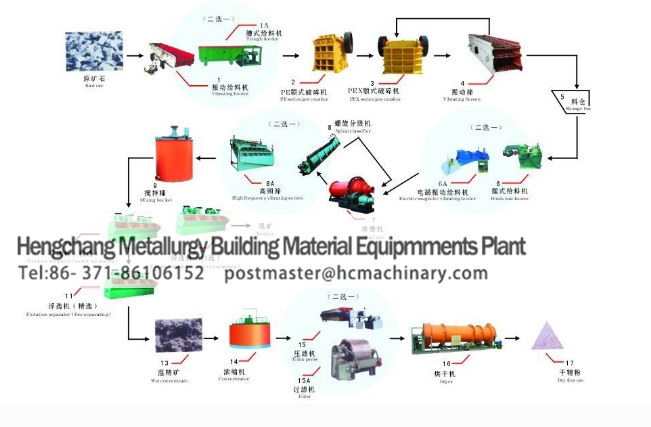

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

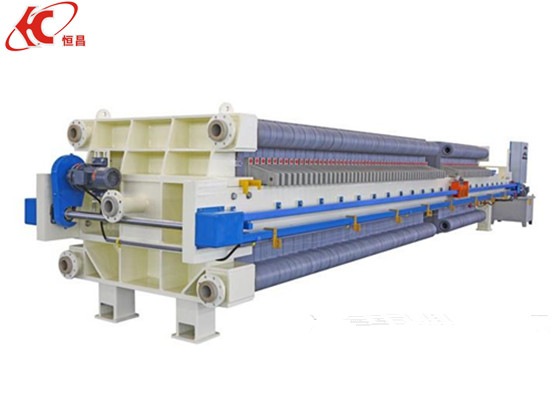

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website