Product introduction

The mobile imapct crusher plant is mainly used for the processing of materials that often require relocation operations such as metallurgy, chemical industry, building materials, and hydropower. It is used for the operation of mobile materials such as highways, railways, and hydropower projects. Users can use a variety of configurations depending on the type of processing materials, size and finished material requirements. The mobile crushing station unit can also be used for secondary crushing according to specific needs combined with coarse crushing mobile crusher or other coarse breaking equipment (jaw crusher, etc.) to timely process the materials.The tire type anti-breaking mobile impact crusher station is especially suitable for small crushing sites, suitable for construction waste disposal and sand making production line.

Product Advantages

1. The equipment is flexible in configuration, and can be independently produced by a single unit, or it can be combined with rough-breaking equipment. In addition to supplying power to the unit, the diesel generators installed in the mobile crusher unit can also be configured to provide combined power supply to the process system, which greatly improves the adaptability of the equipment.

2. The medium-crush mobile crusher unit has a high vehicle chassis, the vehicle body width is smaller than the operating semi-trailer, and the turning radius is small, which is convenient for driving in the rugged road environment of the crushing field, and is more conducive to stationing in the construction area.

3. The configured impact crusher can not only crush a certain first-line material in the field, but also directly produce the finished sandstone material with the ideal granularity. The working range is expanded and the material transfer and transportation cost are also reduced. In addition, the medium crushing mobile crusher extension unit can directly send the broken materials into the transfer car box to facilitate timely transportation.

4. The impact crushing principle of the impact crusher produces a better finished product size, which can significantly improve the overall working efficiency of the mobile crushing station.

5. The medium crushing and mobile impact crusher station unit is installed and integrated, the overall coordination is strong, the space layout is reasonable and compact, which saves time and space for on-site construction, improves flexibility, and eliminates a large amount of site infrastructure, greatly reducing the Investment costs, easy operation and maintenance. The division of equipment configuration equipment is clear, concise and easy to maintain. Working principle: When the crushing operation is carried out by the medium crushing and breaking mobile crusher, the crushed material is directly crushed by the impact crusher to the medium-fine particle size, and the closed-circuit screening circulating system composed of the circular vibrating screen directly produces the ideal finished sand and gravel material, and finally Output by the conveyor to the designated location.

operating principle

The impact crusher uses the impact energy to crush the material. When the motor is driven, the rotor of the impact crusher rotates at a high speed. After the material enters, it collides with the hammer on the rotor, and then is counterattacked to the liner again. Broken and finally discharged from the discharge port. The user can adjust the gap between the counter frame and the rotor frame to achieve the purpose of changing the material discharge size and material shape.

Technical parameters

Model | HC1210 | HC1214 | HC1315 | HC1110 | HC1315 |

Transportation Length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

Maximum Length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

Weight(t) | 39 | 44 | 54 | 62 | 62 |

Impact Crusher Model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

The Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

Production Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

Side-opening Belt conveyor(Optional) | B500×3.2M | B500×3.2M | B650×4M | B650×4M | B650×4M |

Genset(Optional) (kw) | 320 | 320 | 400 | 320 | 440 |

Iron Separator (Optional)(kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

PRODUCTS PRODUCTS

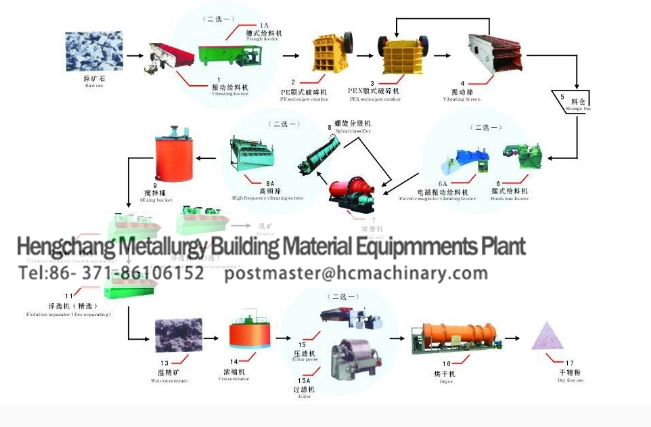

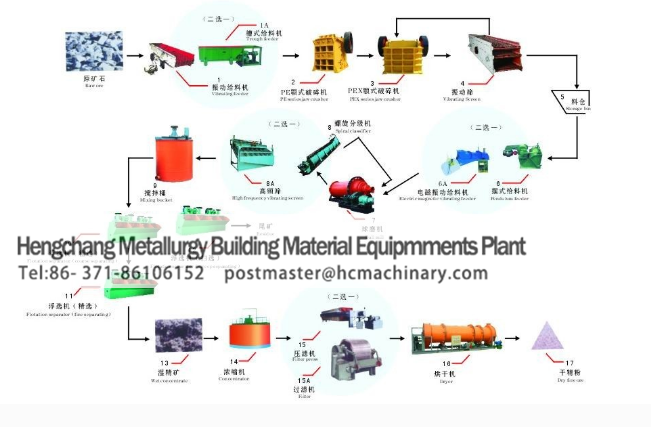

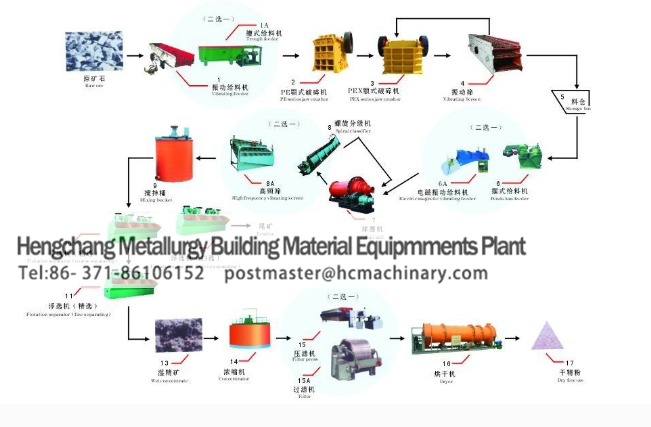

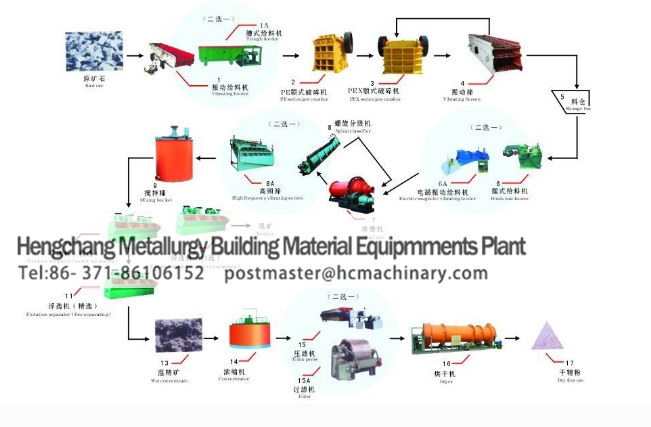

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

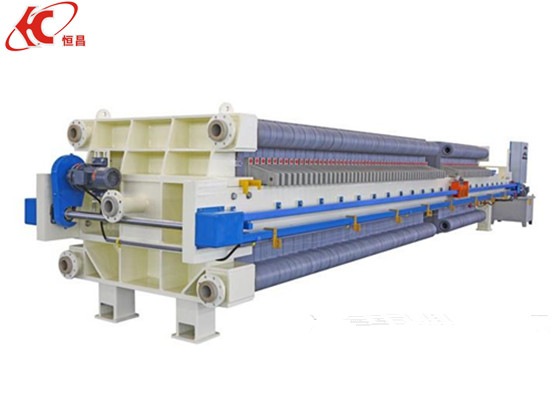

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website