Product introduction

Mesh band belt dryer is a kind of drying equipment which uses steel mesh as transmission belt to carry materials for continuous drying. Because the transmission belt is reticulated, it is most suitable for drying regular or irregular blocks (such as coal, fast molding of various mineral powder, food, vegetables, etc.). This machine can be used with other equipment. You can also use it alone. The utility model has the advantages of small investment, fast drying speed, high evaporation intensity, high efficiency, large output and good product quality.

Product Advantages

The belt dryer can adjust the air volume, heating temperature, material residence time and feeding speed to achieve the best drying effect. The equipment configuration is flexible, can use the net belt washing system and the material cooling system. 3. Net belt dryer most of the air recycling, high energy saving. 4. The unique air distribution device of net belt dryer makes the distribution of hot air more uniform and ensures the consistency of product quality. 5. Heat source can be used steam, heat conduction oil, point or gas hot blast stove matching.

operating principle

The belt dryer distributes the material to be dealt with through the appropriate laying mechanism, such as star distributor, swing belt, grinder or granulator, on the conveyor belt, which is composed of one or more heating units, each of which is equipped with air heating and circulation system, each of which has one or more humidification systems, and when the conveyor belt passes, Hot air passes through the material on the conveyor belt from top to bottom or from bottom to top so that the material can be dried evenly.

Net belt dryer is a batch, continuous production of drying equipment, the main heating methods are electric heating, steam heating, hot air heating. The main principle is that the material is evenly tiled on the mesh belt, the mesh belt adopts 12 × 60 purpose steel wire mesh belt, which is dragged by the transmission device to move back and forth in the dryer, the hot air flows through the material, and the water vapor is discharged from the dehumidification hole, so as to achieve the purpose of drying. in order to save the site, the drying mechanism can be divided into multi-layer type, the common ones are two rooms and three layers, two rooms and five layers. The length is 6 ≤ 40 m and the effective width is 0.6 ≤ 3.0 m.

Technical parameters

Model | Mesh Width(mm) | Drying Length(m)

| Drying Area(m2) |

Layer | Layer Distance (mm) | Running Speed(m/min) | Power(Kw) |

Capacity(t/h) |

HJWD6 | 600 | 6-12 | 3.6-36 | 1-5 | 400-600 | 0.06-1 | 1.1-2.2 | 6-10 |

HJWD8 | 800 | 6-12 | 4.8-48 | 1-5 | 400-600 | 0.06-1 | 1.1-2.2 | 8-15 |

HJWD10 | 1000 | 6-16 | 6-80 | 1-5 | 400-600 | 0.06-1 | 1.1-2.2 | 10-20 |

HJWD12 | 1200 | 8-16 | 7.2-96 | 1-5 | 400-600 | 0.06-1 | 1.1-3 | 12-25 |

HJWD16 | 1600 | 8-22 | 12.8-105 | 1-5 | 400-600 | 0.06-1 | 1.1-3 | 15-30 |

HJWD20 | 2000 | 10-26 | 20-260 | 1-5 | 400-600 | 0.06-1 | 1.5-4 | 18-35 |

HJWD24 | 2400 | 12-30 | 29-360 | 1-5 | 400-600 | 0.06-1 | 3-7.5 | 20-40 |

HJWD30 | 3000 | 12-40 | 36-600 | 1-5 | 400-600 | 0.06-1 | 5-11 | 25-50 |

PRODUCTS PRODUCTS

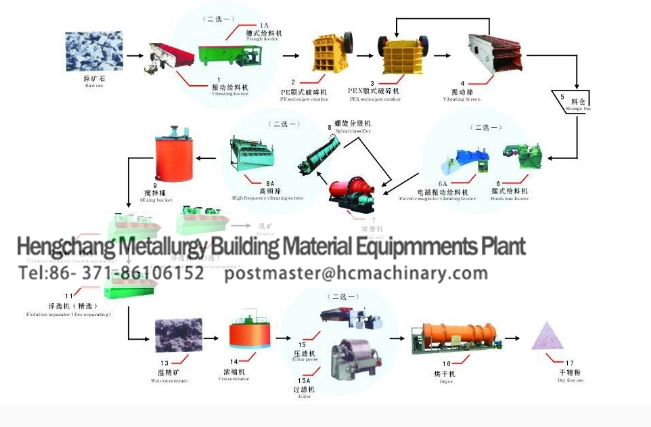

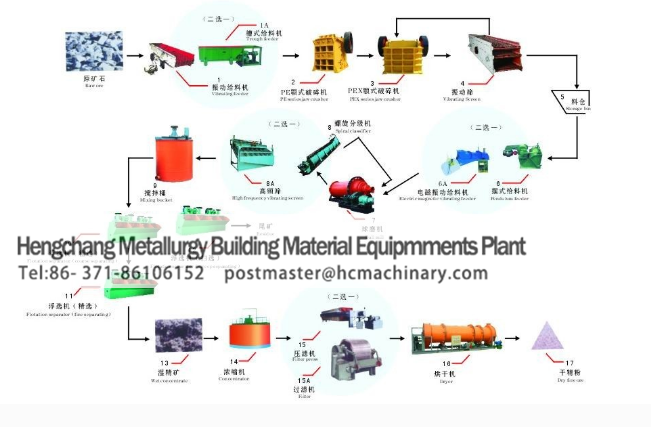

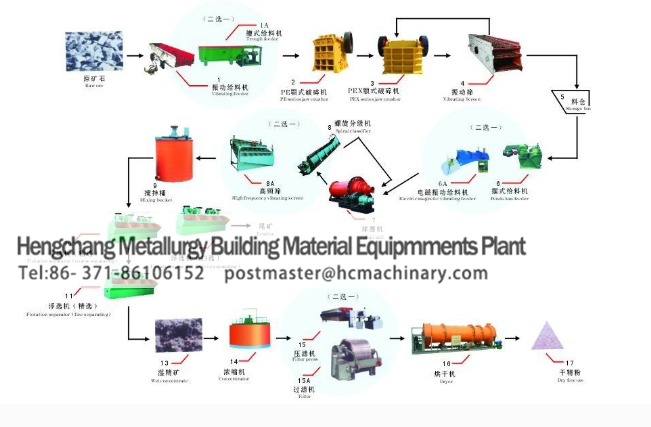

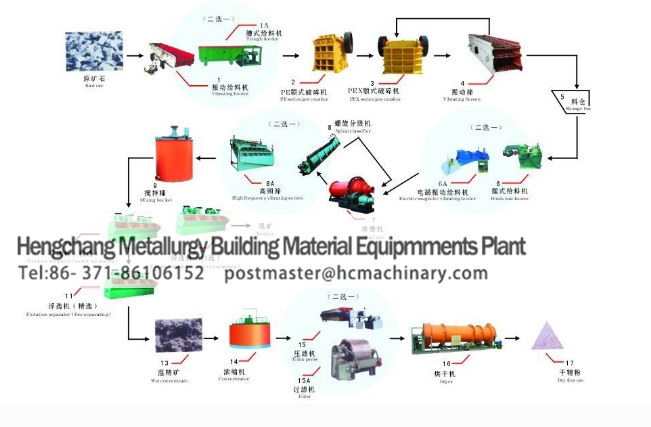

Mineral processing Item

- Ball mill

- spiral classifier

- High frequency screen

- XJK flotation machine

- Inflatable flotation machine

- SF Flotation machine

- Wet magnetic separator

- Leaching tank

- Thickener Concentrator

- Trommel washing plant

- gold centrifugal machine

- spiral chute

- jig machine

- shaking table

- Mixing drum

Stone crushing Item

- Jaw crusher

- Impact crusher

- Spring cone crusher

- Hydraulic cone crusher

- Circular vibrating screen

- Vibrating feeder

- Double roller crusher

- Hammer crusher

- Mobile jaw crusher plant

- Mobile impact crusher plant

- Mobile cone crusher plant

- Sand making machine

- Trommel screen

- Belt conveyor

- Two stage hammer crusher

- Vertical combination crusher

Washing & dewatering Item

- Vibration dewatering machine

- Tailing Thickener

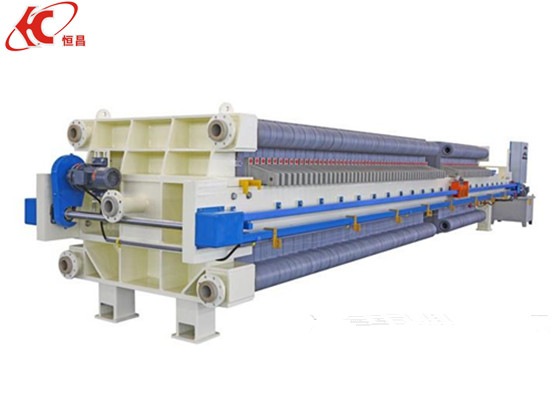

- Filter press machine

- Rotary drum washer

- Spiral washing machine

- Wheel washing machine

Sweep Watch the official mobile website

Sweep Watch the official mobile website